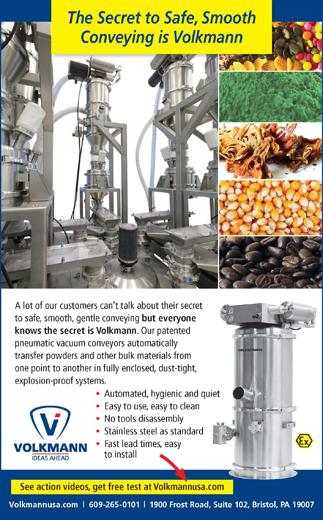

Secret to Safe, Smooth Conveying is Volkmann

A maintenance technician for a major food manufacturer who took on a new job as a chief engineer with a different major food manufacturer asked us about converting the entire material transfer process from a series of open belt conveyors and bucket elevators to our pneumatic vacuum conveying systems. “After so many years using your conveyors, coming over to this plant seemed like it was in the stone age,” said the chief engineer, who signed a non-disclosure and cannot be named. “For a sanitary plant, it was a recall waiting to happen. Replacing everything with Volkmann conveyors was the first order of business.”

We know it’s unsatisfying to read when we can’t put an actual name to the story but nearly all of our customers are either bound by non-disclosures and are not allowed to provide their names or their companies consider our conveying systems a competitive advantage to be kept quiet and under wraps. Magazine editors are always asking us about writing stories showing how a customer uses our conveyors. Our sales people are always trying to get videos of our conveyors installed in live action. The answer is almost always, “No, our Volkmann is our secret,” or something similar.

Last year, when a global pharmaceutical company acquired a growing nutritional supplements company, a process engineer for the big pharma company touring his newly acquired facility was impressed by our pneumatic vacuum conveyors. Our systems were being used to transfer powdered ingredients from bulk bags and sacks to mixers, and again downstream to capture finished tablets at the tablet press, transferring them automatically to the filling line. “I was struck by the cleanliness of the process,” said the process engineer, who couldn’t divulge a name. “That’s why I started adding Volkmann conveyors to every one of my pharmaceutical production lines. The results have been as phenomenal as anticipated.”

Then there’s the chemical engineer who started working with a major chemical manufacturer as an intern while in college. The company was transferring ignitable powders in our pneumatic vacuum conveyor systems from drums and barrels directly into a vessel. “That’s how I learned about the ATEX certification, combustible dust explosions, and how to avoid them,” says the chemical engineer. Nearly 20 years later, the same conveying system continues to operate day and night and the intern is now the plant manager who has specified additional Volkmann vacuum conveyors for a number of material transfer applications. “Volkmann conveyors are explosion-proof by design so I don’t have to worry about keeping my staff safe,” he added. “But it’s all our secret, ok?”

Learn more about conveying your materials here.