Battery Production

Safely handling critical raw materials in the production of battery anode and cathode materials typically starts with removing bagged powders from storage and transferring the battery materials to downstream process equipment. Using a Volkmann pneumatic vacuum conveyor contains the toxic materials inside enclosed piping to prevent operator exposure and safeguard the precious materials from contamination. The battery component materials can be automatically conveyed from bulk bags, sacks, drums, and bins over short or long distances to load a mixer, extruder, hopper or other destination safely, smoothly, and gently to protect particle integrity.

For specific EV battery manufacturing requirements, Volkmann offers unmatched experience as a trusted partner providing proven bulk material handling solutions and process equipment from custom design and engineering, validation in testing, and reliable implementation, to ongoing technical support. In fact, Volkmann continues to provide powder handling systems for transferring critical raw materials to well-known battery manufacturers in Europe, Asia and North America after more than 20 years in service to this industry.

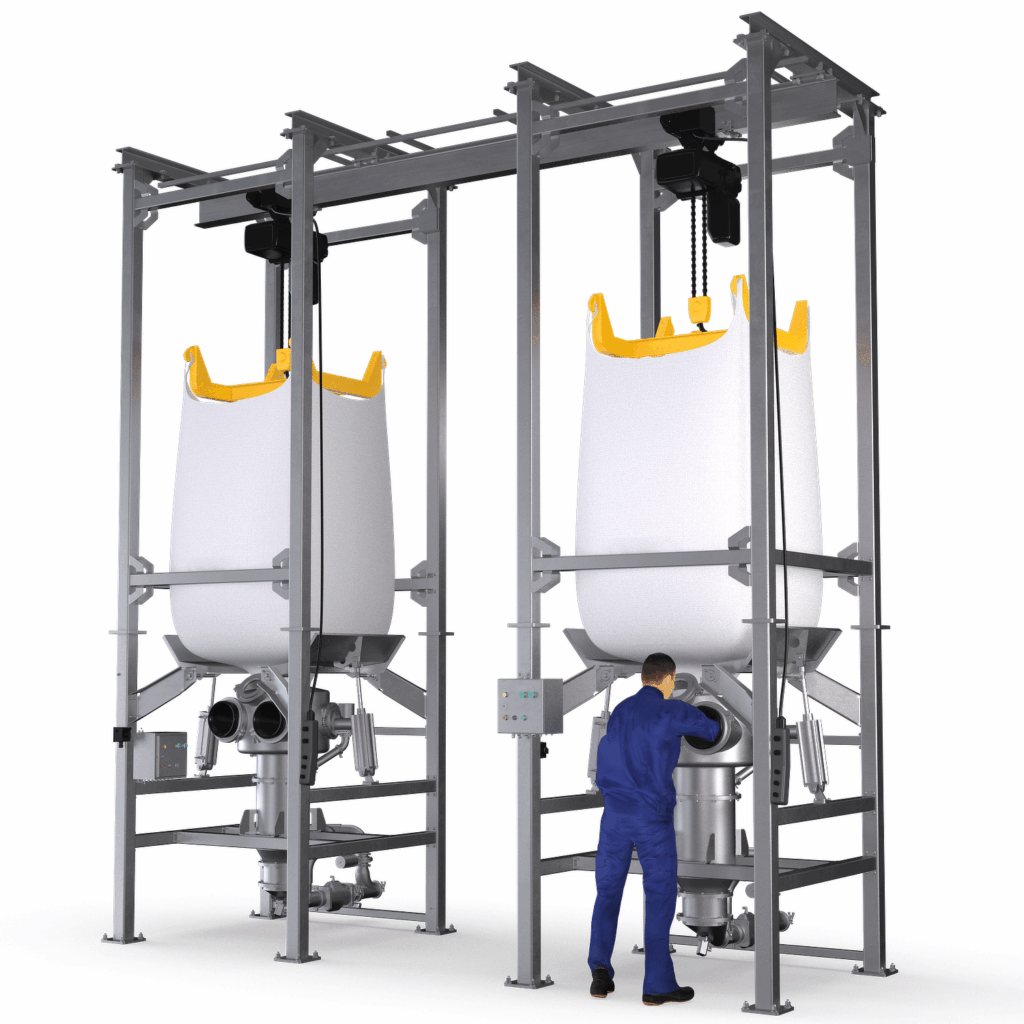

Example of a production area for handling critical anode and cathode material. The material is fed into the processes from bags, drums and big bags. The material is emptied in the corresponding stations and conveyed to the mixers by vacuum conveying through the pipework, weighed and fed into the mixers.

Feeding Metals Used in Batteries

Volkmann offers the companion powder handling equipment needed to automatically feed the raw anode and cathode materials from storage containers into the pneumatic vacuum conveying system. This assures safe, efficient, contained material transfer directly into the production process. The raw material can be fed from:

- Bulk Bags, big bags or FIBCs

- Bags or sacks

- Drums, bottles or containers

- IBC containers

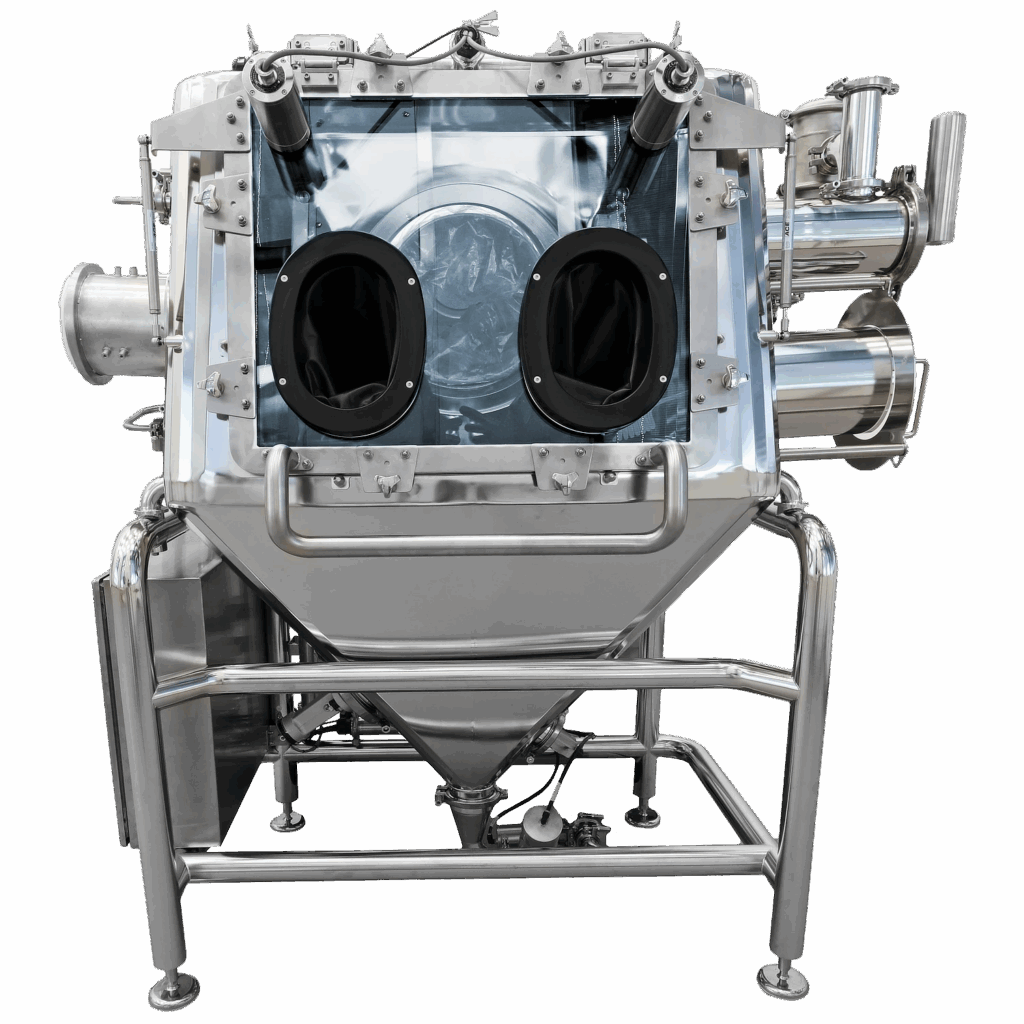

For maximum contamination prevention, Volkmann designed a proprietary containment system that hermetically separates the powder handling area from the operator. This glove box design is particularly important to safely process toxic, hazardous, and, in some cases, carcinogenic, cathode materials such as cobalt, manganese, or nickel.

Vacuum Conveying Handles with Care

Volkmann pneumatic vacuum conveyors automatically transport the raw material through a pipe to a slurry mixer or other location without generating excess friction or heat. The novel design eliminates the need for electricity along with any rotating parts. Only Volkmann generates vacuum as efficiently using the Multijector® ejector pump and compressed air for a powerful suction action that can be scaled from a few kilograms per hour up to 10,000 kg/h. This negative pressure, safety first design ensures explosion-proof and dust-free material handling, and earned the ATEX certification for safe operation in hazardous environments, even when conveying ignitable powders and combustible dust materials.

Where required, pneumatic vacuum conveying can also be carried out with an inert gas such as N2 nitrogen or argon.

Weighing + Dosing

Dosing ensures steady material feed

The conveyed material can be fed into the mixer or other downstream location in a continuous material flow using the Volkmann vibratory feeder dosing system. A key element in the battery manufacturing equipment line, this system integrates a material storage container and vibratory feeder into the vacuum conveying system. The vacuum conveyor transfers the material to the container at preset intervals as the vibrating feeder continuously accepts the battery material from the container and feeds it downstream, timed to match the speed of the processing line.

Weighing the material

The anode and cathode material can be weighed before feeding it to the next station. When this vibratory feeder is used, the feed quantity can be defined with high accuracy. A choice of loss-in-weight (LIW) or gain-in-weight (GIW) may be used. In the LIW concept, a module consisting of a storage container, vibratory feeder and the battery product are weighed with a load cell. The weight changes are monitored and the vibratory feeder is automatically controlled accordingly. With the GIW concept, the mixer or other downstream location is weighed. This value is transmitted to the conveyor system’s PLC via a data interface and the vibratory conveyor is automatically controlled accordingly.

Engineering Solutions for Electric Batteries

In addition to developing and providing powder handling solutions for battery manufacturing and production, Volkmann also provides solutions for powder sieving, mixing, and drying using vacuum technology. And, if needed, parts that are 100% copper and silicone-free may be manufactured. WIP/SIP, inert gas blanketing, and a wide range of sophisticated and custom solutions are offered.

More than 90% of our process equipment is designed, developed, and produced exclusively at our facility in Soest, Germany. Thanks to the close cooperation of our engineering and manufacturing departments, we can supply our customers with the ideal engineered solution adapted to specific needs and targets and deliver with faster than expected lead times. And with our modern technical laboratory, material and equipment testing are offered under controlled environmental conditions to simulate real-world situations as closely as possible whether manufacturing lithium-ion, nickel-metal hydride, solid-state, and/or lead-acid batteries.